Wet Gas Compressor Cooling

Refineries, petrochemical plants, and other industries often use water-cooled compressors as part of their processes. For example, wet gas compressors compress light gases such as butane and propane and deliver them to a cat cracker as a portion of the feed to a reaction chamber. Many compressors are cooled using a water jacket and cooling tower water.

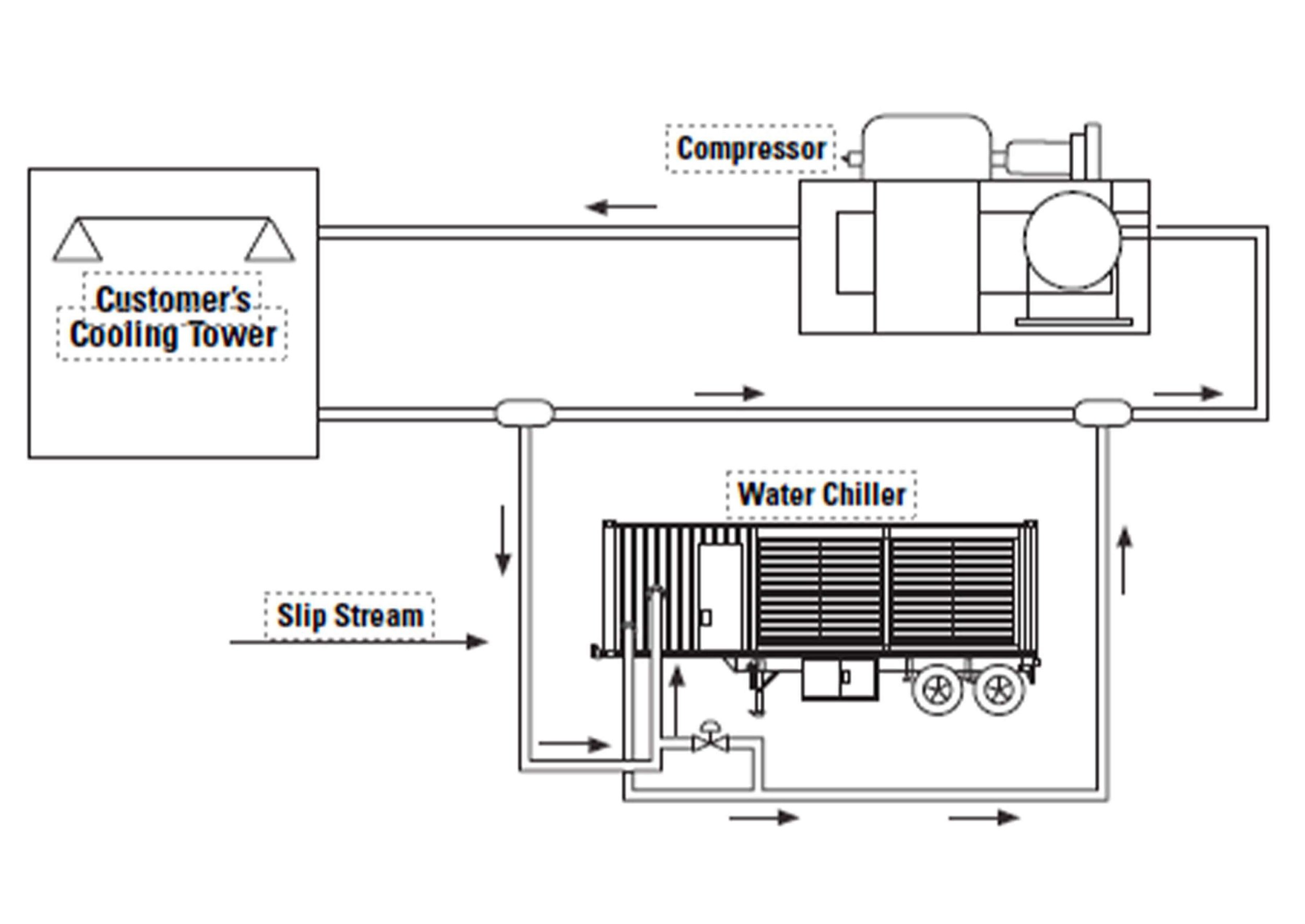

During the summer month, cooling tower water may not provide sufficient cooling, and the compressors can overheat, reducing feed rates to other production processes. Rental chillers connected to the cooling water supply lines can supplement or replace existing cooling. The illustration below shows a typical installation.

Wet Gas Compressor Cooling Installation

Rental equipment typically used for compressor cooling applications includes the following:

Chiller modules ranging from 100 to 500 tons

Pump modules, circulation tanks, recirculation loops, cooling towers, or heat exchanger modules

Piping and fittings

Engineering and supervision services

Installation and maintenance services

On-site operation and training

Typical Customers:

Oil refineries are the principal customers for wet gas compressor cooling applications.

Discovery Questions

Can you maintain constant feed rates from your compressors, or are they limited by the performance of your cooling towers?

What types of cooling systems do you use to cool your gas compressors? Are you planning for any system maintenance, repairs, or retrofits?

What type of backup plan do you have in case of cooling equipment failure? How much revenue will you lose each day that your cooling systems are offline?

Configuration and Installation Issues

Supplemental cooling applications typically operate in parallel with the customer’s cooling system. Determine the required inlet and outlet temperatures and pressures when sizing the chiller. A pump and recirculation loop may also need to be added to the circuit to prevent inlet temperatures in excess of 65 degrees Fahrenheit.