Product Storage

Many industries rely on cool room facilities (38° F to 40° F) for storage of perishable products. These facilities typically use chilled water or refrigeration equipment to produce the necessary cooling.

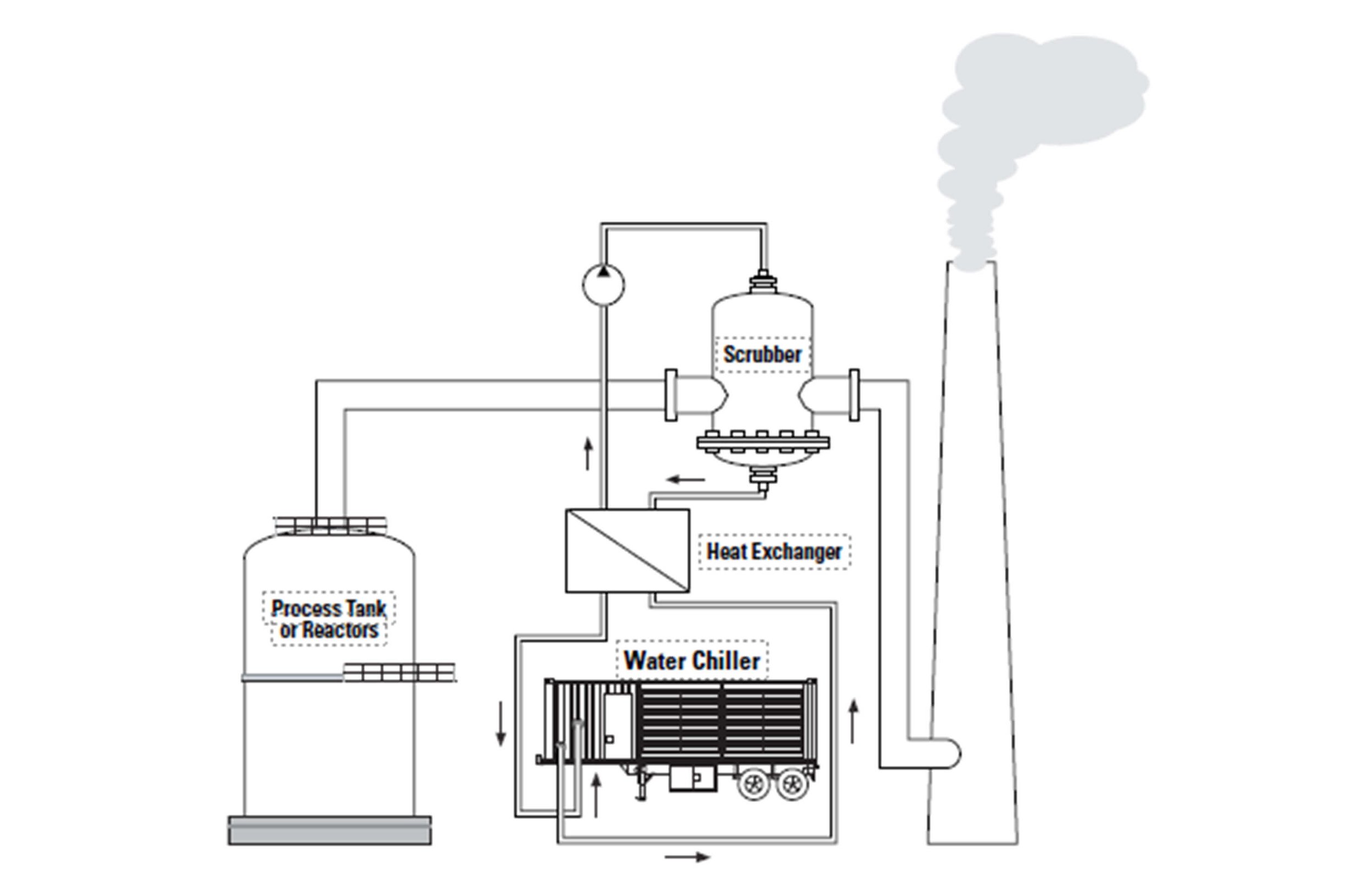

Scrubber Cooling

Scrubbers use a solution to remove chemicals from gases within a tank. A scrubber must be cooled to maintain low emission and high production levels.

Jacketed Reactor Cooling

Companies that produce chemicals or pharmaceuticals use reactors. Water or brine is usually circulated through the reactor jacket or coils to control the heat of the reaction. Without sufficient cooling, reactor operations might have to be shut down.

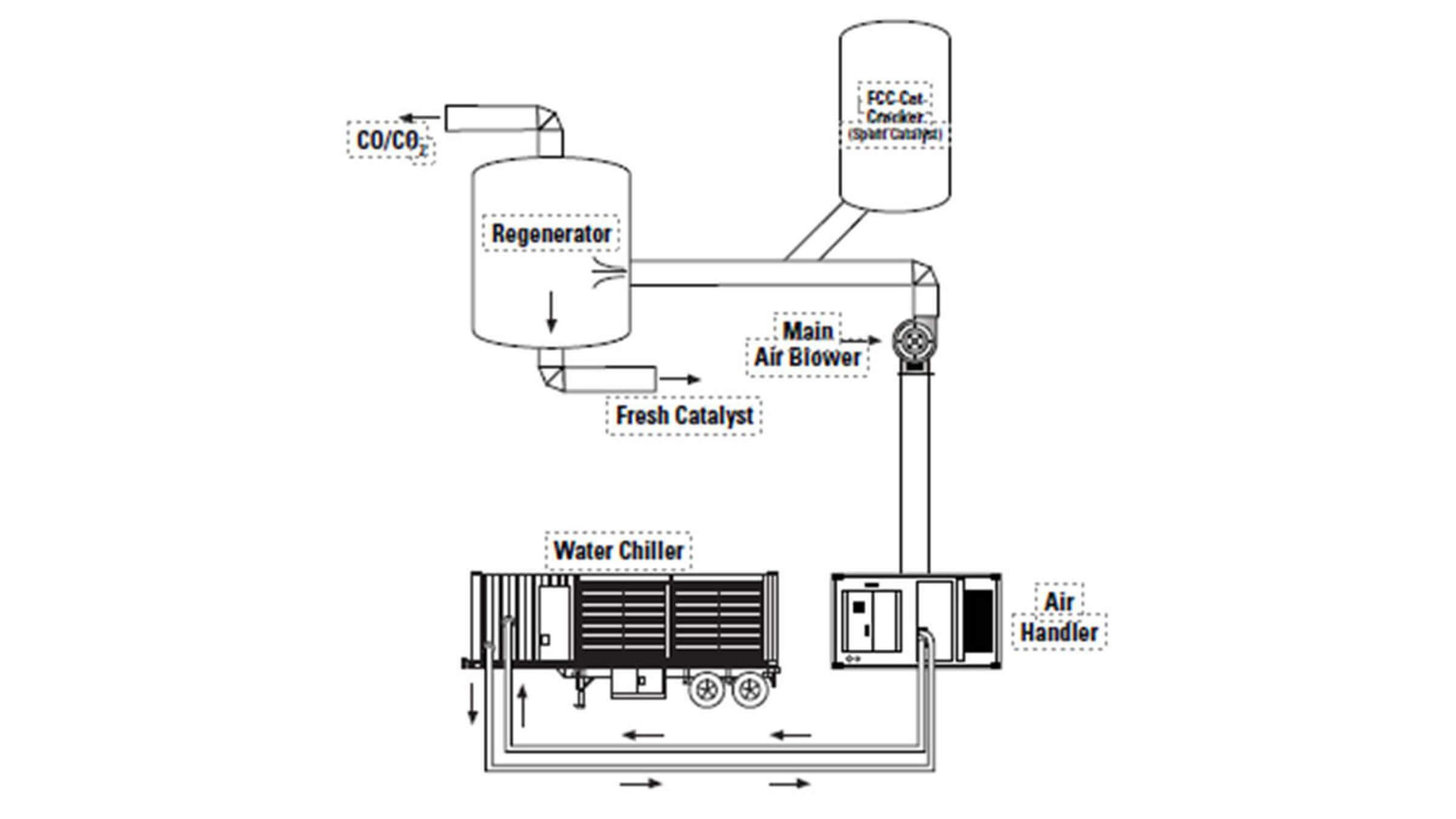

Dense Air Injection

During summer months, air is less dense, resulting in less oxygen per cubic foot of ambient air. Production rates can be maintained by chilling the air and blowing it into the process.

Cool Air Supplied for Confined Spaces

Ventilation, air conditioning, and dust control are now required by OSHA and other regulatory agencies for vessel, refractory, underground mining, and tunneling operations.

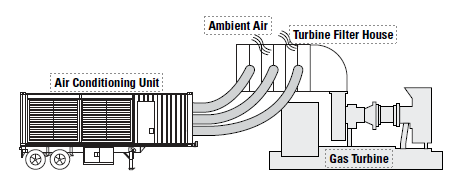

Turbine Inlet Cooling

Many industries use gas turbine engines to power a variety of compressors, generators and other equipment. These engines require large amounts of oxygen to run efficiently.

Conveyor Cooling

In certain types of manufacturing, products must be cooled as they move on conveyor systems. The faster the products cool, the faster the conveyors can move, which affects production levels.

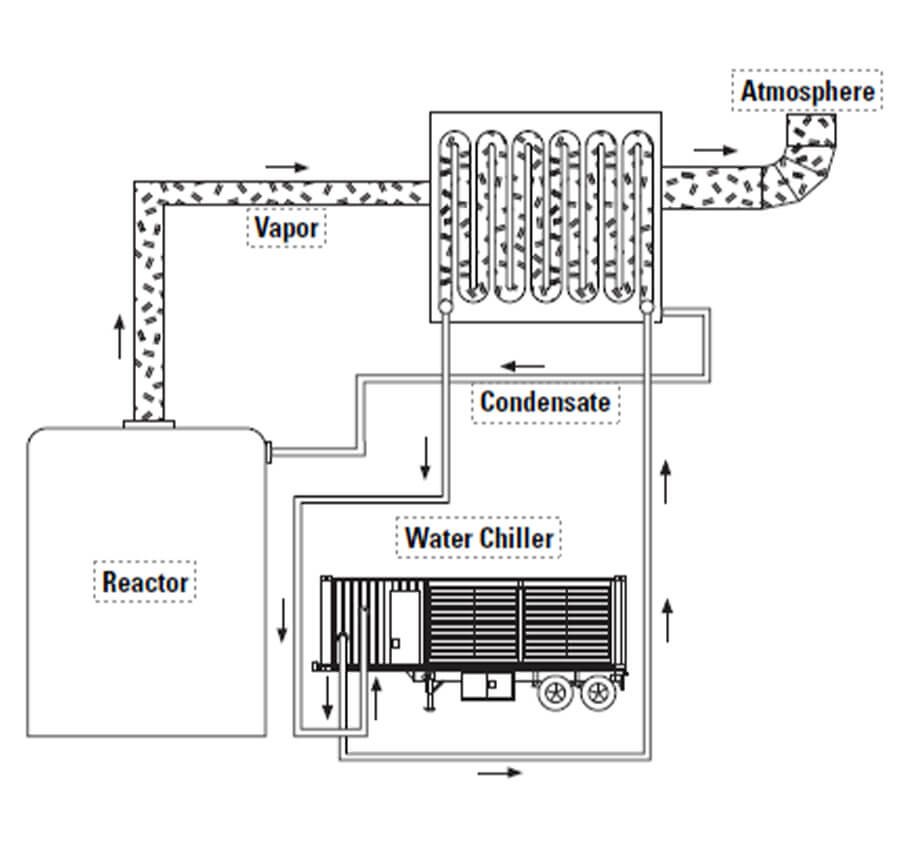

Condenser Cooling

During summer months, the existing cooling equipment is stressed and may not keep up with demand, requiring cutbacks in production. Rental chillers can provide both backup and supplemental cooling capacity. The drawing below shows one possible installation.

Waste Water Treatment

A widely used method of treating wastewater is through treatment ponds, where bacteria break down the waste materials. These microorganisms are heat sensitive and die if the pond gets too hot.

Vapor Recovery and Liquefied Gas Storage

Liquefied gasses such as butane, propane, natural gas and others are condensed and stored in large pressurized tanks. A portion of this liquefied gas boils off as vapor, both during production and storage and must be re-condensed and returned to the storage tank.

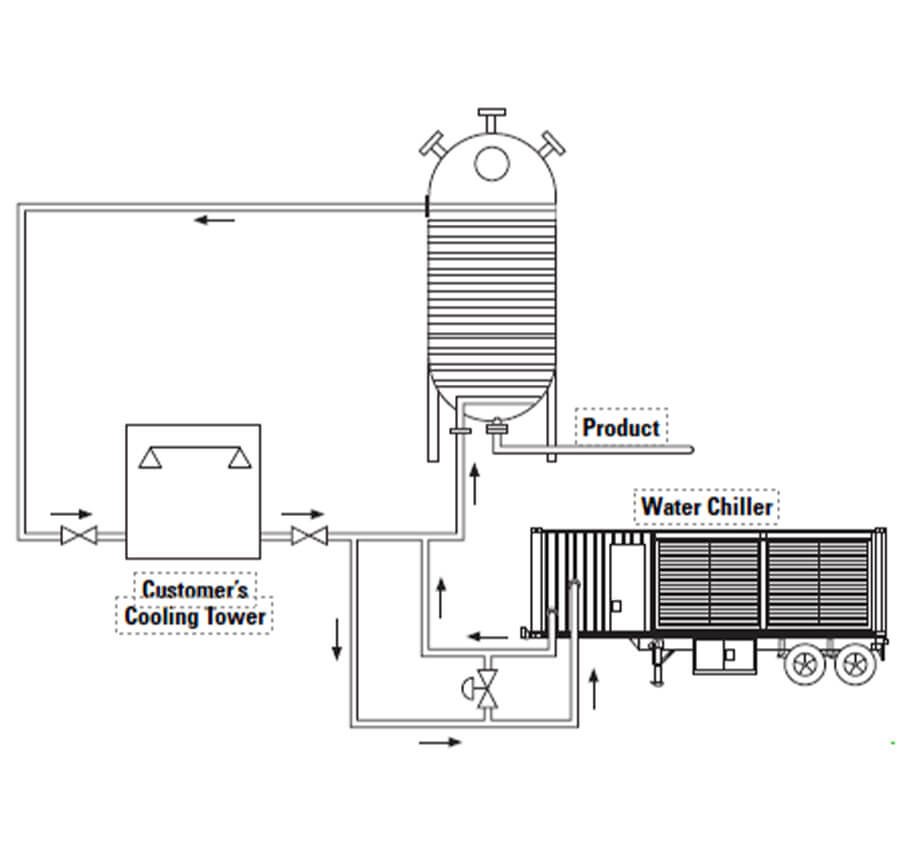

Supplemental Cooling Tower Water

Rental chillers are the ideal solution to supplement cooling tower capacity and lower water temperature sufficient to support production processes.

Cold Room Storage

Many industries rely on cool room facilities (38° F to 40° F) for storage of perishable products. These facilities typically use chilled water or refrigeration equipment to produce the necessary cooling.